Plastic Injection Moulding Dies Manufacturers, Suppliers & Exporters in India, Dubai, UAE

Shiva Tech Engineering is the leading Plastic Injection Moulding Dies Manufacturers, Suppliers, Exporters in India, Dubai, UAE. Get Details of Plastic Injection Moulding Dies

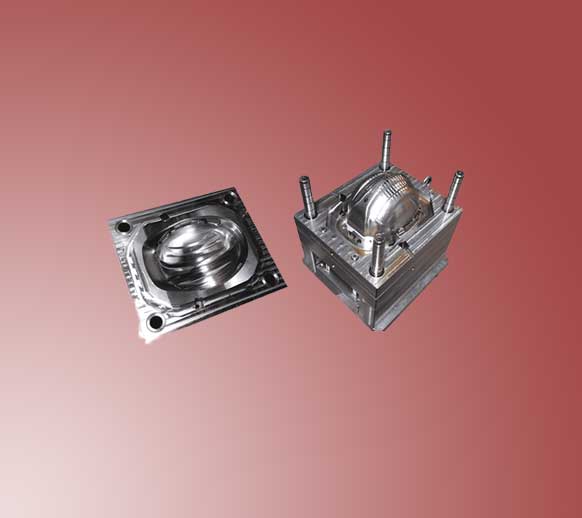

Manufacturers of Plastic Injection Moulding Dies Manufacturers, Suppliers, Exporters in India, Dubai, UAE. Plastic Injection Moulding Dies in India is a manufacturing process in which molten plastic is forced into a mould cavity under high pressure and then cooled and solidified to form various plastic components or products.

The moulds used in our process are made of steel and consist of two parts, the cavity and the core. The components and dies used for our injection moulding are crucial in determining the quality and success of the manufacturing process.

Plastic Injection Moulding Dies Manufacturers & Exporters in India, Dubai, UAE

Features

- Durability: Materials used for manufacturing must have a high level of durability to withstand the repetitive processes used in mass production.

- Precision: These are very precise, to produce components or products that conform to strict specifications and dimensions.

- Compatibility: The components and dies should be compatible with a wide range of plastic materials and machinery.

- Heat resistance: These components and dies should be heat resistant so that they can withstand high temperatures without losing their properties.

- Uniformity: Uniformity in design is crucial to ensure consistent results in every production run.

Industrial Uses

- Automotive parts manufacturing: Used to manufacture components such as dashboards, door handles, and bumpers for the automotive industry.

- Home appliance manufacturing: Various plastic components in household appliances such as washing machines, refrigerators, and microwaves are produced using injection moulding.

- Medical equipment: such as syringes, test tubes, and medical devices are produced using injection moulding.

- Packaging manufacturing: such as lids, bottle caps, and container bodies.

- Consumer products: Many consumer products, including toys, electronic devices, and packaging materials, are produced using injection moulding.

Specifications

| Usage/Application | Industrial |

| Cavity | Single, Double, Multi Cavity |

| Product Material | Plastic, PP, ABS |

| Shape | Rectangular |

| Color | Multi |

| Size | Customised |

Product Description

Our company has received customers' appreciation for providing Plastic Moulding Dies in various sizes and shapes. These dies are appropriate for use and unaffected by high pressure or other outside factors.

Features

- Easy to use

- Accurate measurement

- Reliable

Frequently Asked Questions

Injection moulding begins with fabricating a tool, also known as a mould, and precision-machining it out of either steel or aluminium Mould. Mould or die are the common terms used to describe the tool used to produce plastic parts in moulding. A machine function places the tool into the injection moulding machine.

In maximum production runs the moulding process produces parts generally in finished condition with the manufacturing proceeding complete unless the part needs other finishing steps, such as painting. Plastic injection moulding is a huge saving-money measure as multi-step manufacturing proceedings can be extremely costly.

Simply, it's a manufacturing proceeding that helps to produce a large number of moulding parts as per the requirements. They also manufacture moulds to be used in this process and help to make parts at the best pricing range.

Plastic injection moulding is one of the most accessible and cost-effective options for producing large volumes of parts. It ensures products are commonly in the finished condition which means you don’t need more finishing steps.

8- 10 weeks on minimum, depending on the complicacy and cavitations of the mould.

You may send the order details by contacting us at sgombimath@gmail.com or call us at 919764881012.

Our Products

India

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines

Dubai

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines

UAE

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines