Non Ferrous Forging- Manufacturers, Suppliers & Exporters

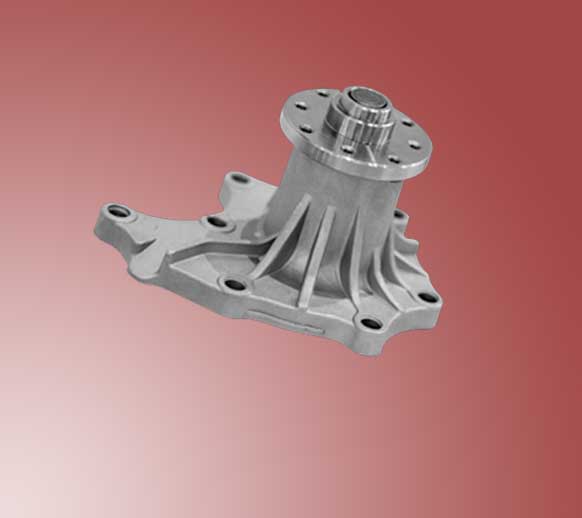

Shiva Tech Engineering is the leading Manufacturers, Suppliers, Exporters of Non Ferrous Forging in India. Our forging is widely used in the aerospace industry for it lightweight, high strength, and corrosion-resistant properties. It also has high conductivity and weather resistant properties.

Non Ferrous Forgings Manufacturers, Suppliers, Exporters by Shiva Tech Engineering in India. Our Non Ferrous Forging in India is the process of shaping or forming non-ferrous metals such as aluminium, brass, copper, and nickel alloys into different shapes using compressive forces.

Non Ferrous Forging in India

Properties

- Lightweight: Non-ferrous metals are much lighter than ferrous metals such as steel and iron, making them an ideal choice for applications where weight is a critical factor.

- Corrosion-resistant: Our Non Ferrous Forging is highly resistant to corrosion, helps to retain the appearance and strength even after long-term exposure to harsh environmental conditions.

- Ductile: It can easily form metals into different shapes without losing their strength or toughness.

- High conductivity: These have excellent electrical and thermal conductivity, making them useful in applications in the electrical and electronics industries.

- Non-magnetic: Non-ferrous metals are non-magnetic and do not interact with magnetic fields.

Industrial Applications

- Aerospace

- Automotive

- Electrical and electronics industry.

- Marine industry

Product Description

We provide high-quality Non Ferrous Forgings that are widely recognised in the marketplace for their quality. According to national and international standards of quality, the finest brass, copper, and aluminium are used to make our non-ferrous forging. Our non ferrous forgings are available in a variety of dimensions and can be customized according to the requirements of clients.

Specifications

| Casting Method | Sand Casting |

| Casting Metal | Iron, Steel, Alloy Steel, Aluminium |

| Surface Treatment | Sand Blast/td> |

| Casting Form Material | Grey, Ductile Iron, Steel, Alloy Steel, Aluminium |

| Casting Form Usage Count | Permanent |

| Brand | Shiva Tech Engineering |

| Country of Origin | Made in India |

Frequently Asked Questions

Shiva Tech Engineering offers the best time-to-market in the industry. New product launches can be achieved in as little as a minimum couple of weeks if necessary.

Yes. Shiva Tech Engineering is ISO 9001:2015 certified.

a part of the material is heated under high pressure in an electric furnace( kiln). Accordingly that it may be moulded into condition at a lower temperature than would usually be needed for casting or welding processes, which causes it to melt at kindly low temperatures.

Yes. Shiva Tech Engineering offers testing and check up services in- house and from outside partners as required. In- house, we offer magnetic particle checkups, pull testing, hardness testing, hand inspections, 3D laser scanning, CMM, and etc.

At Shiva Tech Engineering Forging, we can alloys of aluminium, alloys of copper, alloys of Nickel (Nimonic) and alloys of Titanium.

We run gravity- drop- style hammers and mechanical forging presses that use impress dies to form our products.

You may send the order details by contacting us at sgombimath@gmail.com or call us at +91 9764881012.

Our Products

India

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines

Dubai

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines

UAE

- Low Pressure Die Casting

- Aluminum Die Casting

- Gravity Die Casting

- Precision Machined Components

- Finished Machined Components

- High Pressure Die Casting

- Die Patterns

- Aluminium Alloy Casting

- Die Mould & Patterns

- Plastic Injection Moulding Dies

- Brass Alloy Machine Components

- Sheet Moulding Compound

- Non-Ferrous Forging

- Ferrous Forging

- Die Moulds

- Plastic Injection Moulded Components

- Copper Alloy Machine Components

- Dough Moulding Compound

- Low Pressure Die Casting Machines