Low Pressure Die Casting Manufacturers in India-Low Pressure Die Casting India

We are Low Pressure Die Casting Manufacturers, Suppliers, Exporters in India|Shiva Tech Engineering Pune, Maharashtra, India

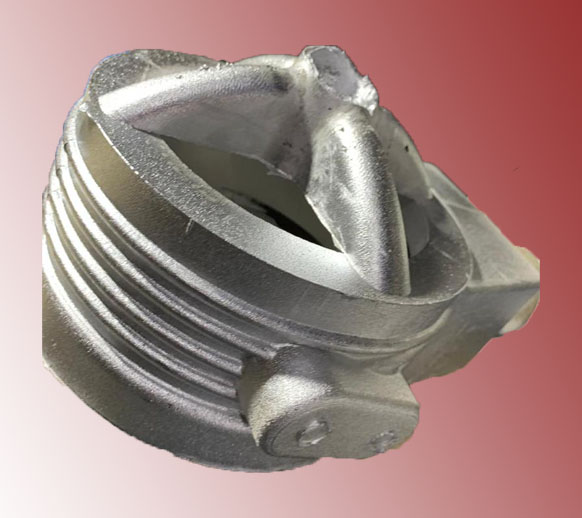

We are offering Low Pressure Die Casting Manufacturers in India. Shiva Tech Engineering is the Low pressure die casting manufacturers, suppliers, exporters in India. We are the professional supplier of Low pressure die casting in India with fully machined parts.We have the capacity to produce up to 100kg of die castings through Gravity Die Casting.

Our Low Pressure Die Casting Manufacturers in India have also installed advanced in-house equipment required for the aluminum casting process, such as sand core blasting, heat treatment, shot blasting, gas leak testing, helium gas testing, CNC machining/ VMC/HMC, vibration finishing, painting, polishing.

Low Pressure Die Casting Manufacturers, Suppliers, Exporters

Low-pressure die casting (LPDC) in India is a metal casting process used to produce high-quality, complex, and near-net-shape metal components. It is a variation of the traditional high pressure die casting (HPDC) process, which involves injecting molten metal into a die cavity at high pressures. In low-pressure die casting, the molten metal is forced into the die cavity at lower pressures, typically between 0.5 and 2 bars (7.25 to 29 psi), which makes it suitable for casting delicate and intricate parts with less porosity and improved surface finish.

What is Low Pressure Die Casting?

Low Pressure Die Casting is a metal casting process that uses low pressure to inject molten metal into a mould cavity. Some features of low pressure die casting are: -

Uses

- • Low Pressure die casting uses a closed mould that is connected to a furnace through a feeding tube.

- • It applies low pressure (usually between 0.1 to 1 bar) to the molten metal in the furnace, which rises through the tube and fills the mould cavity.

- • It allows for precise control of the filling speed and pressure, which can be adjusted according to the part geometry and properties.

- • It produces high-quality castings with complex shapes, thin walls, high strength, high dimensional accuracy, less slag, and no pores.

Benefits

- • High yield and material utilization, as no feeders are needed and less metal is wasted for the gating system.

- • Short cycle time, as the mould is cooled by water or air and the solidified part can be ejected quickly.

- • Suitable for automation, as the process is simple and reliable, and requires less manual intervention.

- • Environmentally friendly, as it reduces energy consumption, emissions, and noise.

Specifications

| Product Name | Low Pressure Die Casting |

| Brand | Shiva Tech Engineering |

| Casting Type | Low Pressure |

| Pressure (in PSI) | 2.9 – 14.5 |

| Usage | Industrial |

Frequently Asked Questions

Low pressure die casting is a method of filling molds with molten metal using pressure instead of gravity.

Our Low pressure die casting can produce high accuracy, high purity, and high strength castings with less waste and less machining.

Our Low pressure die casting uses a holding furnace, a riser tube, and a vertical die casting machine.

Low pressure die casting is suitable for producing large and complex parts such as engine blocks, cylinder heads, wheels, and chassis components