Die Mould and Patterns Manufacturers, Suppliers, Exporters In India

The mold industry in India has evolved over the years and now occupies an important position in the global manufacturing landscape. Shiva Tech Engineering, the leading Die Mould and Patterns manufacturers, suppliers, exporters in India.

Faced with the specific needs of several booming sectors, our Die Mould and Patterns exporters in India can serve various industries including automotive, plastics, electronics and electrical, healthcare and machine tools, the industry is rife with opportunities.

Description

Moulding is one of the oldest manufacturing processes.This is the first step in the production of most products. The steps involved in moulding of Dies & Patterns are: -

- - Create mold cavity

- - The material is first liquefied by heating properly in a suitable furnace.

- - The liquid is poured into the prepared mold cavity.

- - allowed to solidify.

- - The product is taken out of the mold, cut and shaped.

Benefits

- • Molten material can flow into very small parts, allowing complex shapes to be created.As a result, many other activities, like machining, forging, and welding can be minimized.

- • Ability to mold virtually any material:ferrous or non-ferrous metals.

- • The tools needed for molding are very simple andcheap.So, to produce a small batch, this is the ideal process.

- • Some parts (like turbine blades) are made from metals and alloys can only be treated this way.

- • Turbine blades:Fully cast + final machining.

- • Product size and weight are not limitations in the molding process.

Product Specifications

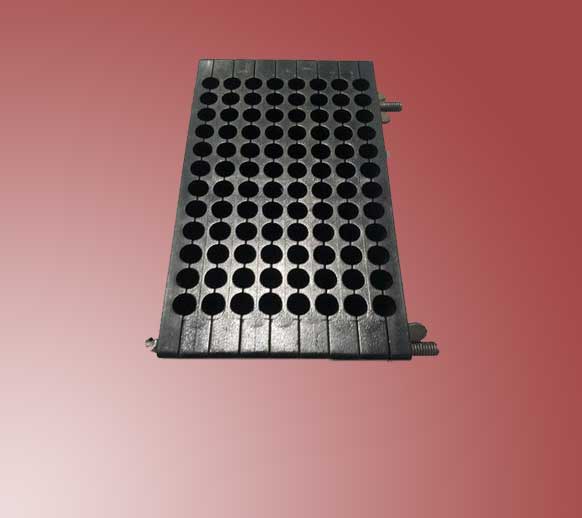

| Product Name | Die Mould and Patterns |

| Brand | Shiva Tech Engineering |

| Finishing | Powder Coated |

| Material Type | Metal |

| Usage | Industrial |

Frequently Asked Questions

A: Die moulds and patterns are tools that are used to shape metal or resin parts by different casting processes.

A: Die moulds are the containers that hold the molten material and form the final shape of the part, while patterns are the models that create the shape of the mould cavity.

A: Die moulds can be classified into different types based on the casting process, such as injection moulds, pressure die moulds, centrifugal moulds, continuous moulds, etc.

A: Patterns can be classified into different types based on the material, shape, design, and usage, such as wood patterns, metal patterns, plastic patterns, wax patterns, single-piece patterns, split patterns, match-plate patterns, cope and drag patterns, etc.