Brass Alloy Machine Components Manufacturers, Suppliers, Exporters In Dubai

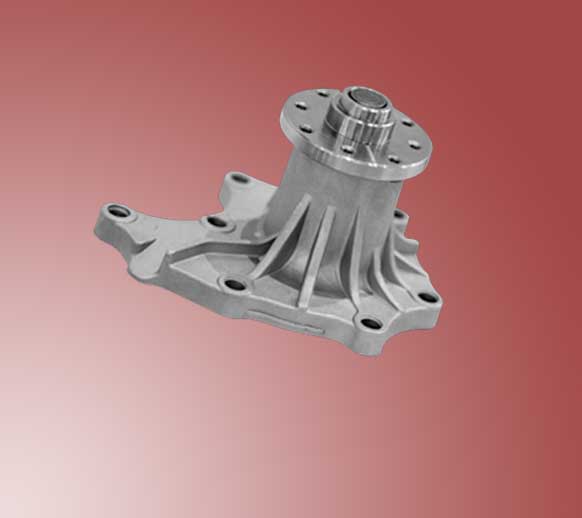

Shiva Tech Engineering has been the leading brass alloy machine components manufacturers, suppliers, exporters in Dubai. We non ferrous forging manufacturers in Dubai undertake specialized non-ferrous metal forging, heat treatment, shot blasting, powder blasting and machining, all under one roof.

We have grown and developed into a well-equipped forging and machining facility.Equipped with machines that make a difference, our non-ferrous metal forging in Dubai is free from porosity, free from surface impurities, have high strength and ductility and above all are competitive about costs.

What does Non Ferrous Forging mean?

Non-ferrous forging is the process of shaping metals or alloys that do not contain iron by applying pressure or impact. Some features of non-ferrous forging are: -

- • Our non ferrous forging can produce complex shapes and fine details with high accuracy.

- • It can improve the mechanical properties and grain structure of the forged material.

- • Our forging can reduce the material waste and energy consumption compared to other methods.

Benefits

- • Our forging can produce lightweight and strong parts that are suitable for aerospace, automotive, and marine applications.

- • It can produce parts that have high conductivity, corrosion resistance, or non-magnetic properties, depending on the material used.

- • It can produce parts that have better surface finish and aesthetic appeal than other methods.

Specifications

| Product Name | Non Ferrous Forging |

| Brand | Shiva Tech Engineering |

| Metal Type | Non Ferrous |

| Density Range | Low |

| Application | Industrial |

Frequently Asked Questions

A: Non ferrous forging is a process of shaping metal parts by applying pressure or impact on non ferrous metals, which do not contain iron or have a low iron content.

A: Our Non ferrous forging offers advantages such as high corrosion resistance, low density, high thermal and electrical conductivity, and non magnetic properties.

A: Non ferrous forging faces disadvantages such as high cost, limited material options, thermal stress, porosity, and distortion.

A: Non ferrous forging can be classified into two main types: hot forging and cold forging, depending on the temperature of the metal.